Qq-p-416 type ii 313610-Qq p 416 type ii

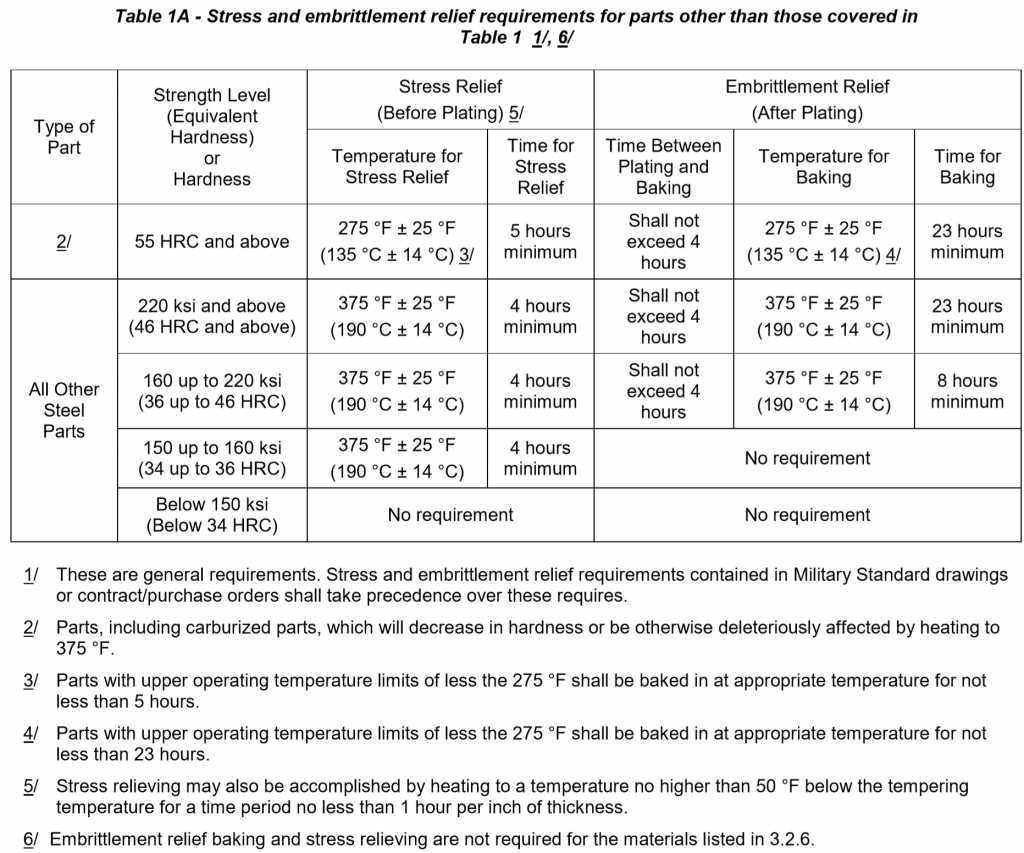

Rationale Revision E of AMSQQP416 corrects the errors in Table 1a and removes the "24 hours minimum" from the drying time requirement of 3281 I have a question and someone can help clarifying the definition of a lot in accordance with AMSQQP416 Para 4421 as follow "Lot shall consist of plated articles of the same basis metal composition, class, and type plated and treated under the same conditions and submitted for inspection at one time"Flat Head Machine Screw with Plate per QQP416, Type II 100 Degree Check up to five results to perform an action larger image Results Per Page 25 50 100 0 Results 1 25 of 94

Nas333 And Nas334 Ga Screws Aircraft Spruce Canada

Qq p 416 type ii

Qq p 416 type ii- qqp416f (notice 1), federal specification plating, cadmium (electrodeposited) (28 mar 02) s/s by saeamsqqp416 Future acquisition for this item should refer to SAEAMSQQP416, "Plating Cadmium (Electrodeposited)" (Application for copies of SAE Aerospace Material Specifications should be addressed to SAE, 400 Commonwealth Drive QQ P 416 F Superseded View Superseded By Superseded A superseded Standard is one, STRAIGHT THREAD TUBE FITTING BOSS, TYPE II HYDRAULIC (MINUS 65 DEG F TO PLUS 275 DEG F) FF B 575 C BOLTS, HEXAGON AND SQUARE MIL T 460 0 TRANSDUCER, MOTIONAL PICKUP TRU164/A MIL C 125/9 A CONNECTORS,

Buerklin Com

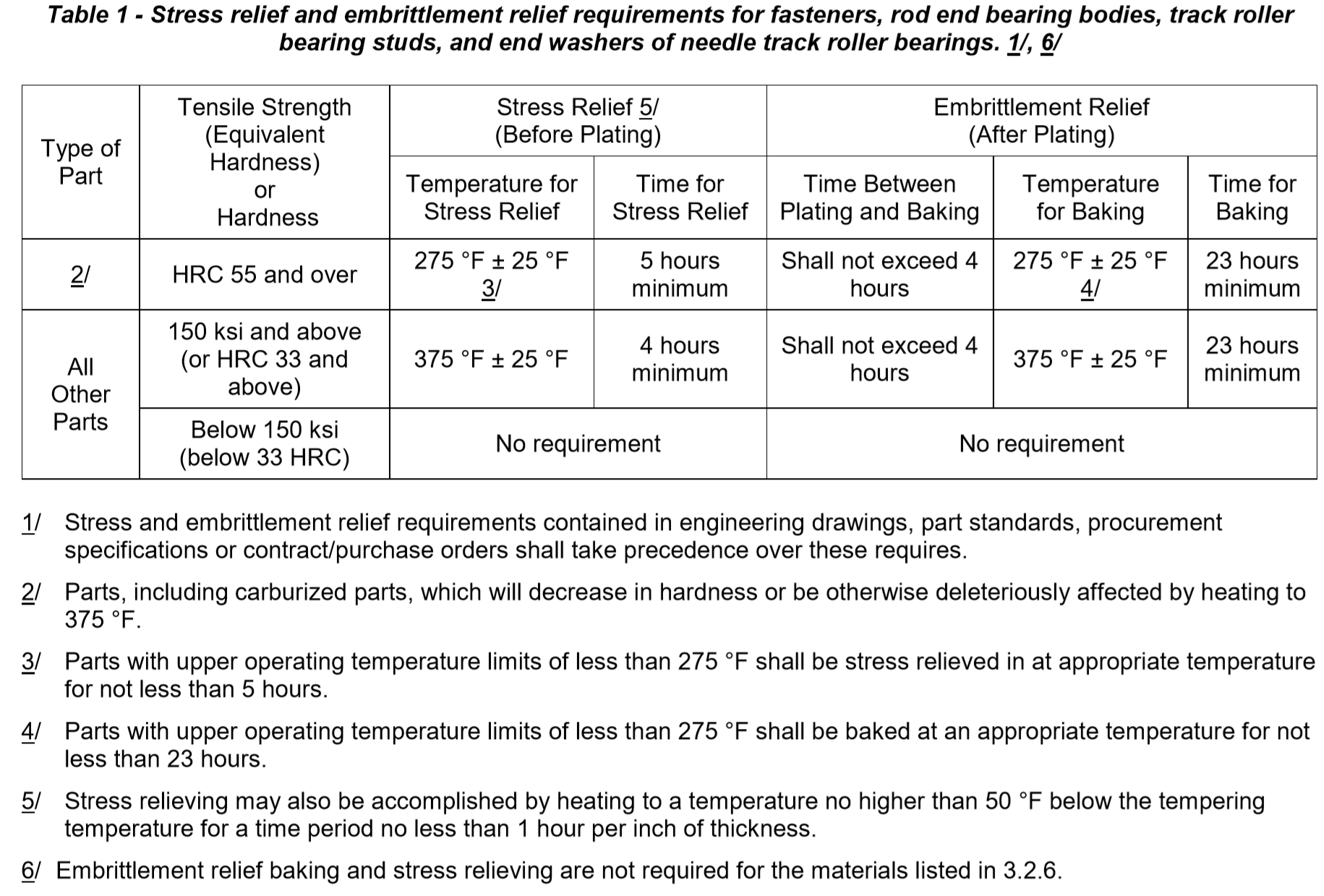

The cadmium plating shall be Type II on parts that will not subsequently be completely coated and Type III on parts that will subsequently be completely coated (see 522 and 523) 3281 Chromate Treatment The chromate treatment required for conversion to Type II shall be a treatment in or with an aqueous solution of salts, acids,QQP416 AMSQQP416 Class I " minimum thickness Class II " minimum thickness Class III " minimum thickness Type I As plated Type II With chromate treatment Type III With phosphate treatment Colorless Irridescent Bronze Brown Olive Drab Yellow Forrest Green Primarily used to protect steel and cast iron againstQQP416E Type Class Lot hydrogen embrittlement testing if required (see 442) and sampling Basis metal to be plated Tensile strength or hardness of the basis metal Preplate stress relief to be performed by plating processor (time and temperature) Special features, geometry or processing present on parts that requires special attention

Cadmium plating is an attractive, soft coating that can be deposited on various base materials, up to and including steels, copper and different types of iron Moreover, it is one of the few deposits that is sacrificial, excelling in corrosion protection With natural lubricity, Cad plating also provides antigalling and low friction propertiesApprovals – California Technical Plating Corp Prime Approvals Cadmium, Electrodeposited QQP416 Types I, II CalTef SP1000 Chemical Conversion Coating MILC5541 Class 1A, Class 3QQP 416 Class 3, Type II The parts shall be capable of passing a 96 hour salt spray test to white corrosion and a minimum of a 0 hour salt spray test to red rust per ASTM B117 Typically, cadmium plus yellow chromate offered by PEM is 0002″ to minimum of cadmium applied to all significant surfaces

SPECIFICATION QQ – P – 416 / AMS – QQ –P – 416 Class 1 THICKNESS" min Class 2 THICKNESS" min Class 3 THICKNESS000" min Type I DETAIL As plated, no chromate Type II DETAIL With supplementary chromate treatment (SPI provides clear, gold and olive drab chromate) Type III DETAIL With supplementary phosphateCadmium Type I, II Class 1, 2, 3 AMSQQP416 *QQP416 Electrodeposited Cleaning Surface Treatments MILS5002 TTC490 Chemical/Abrasive High Humidity Testing AMSSTD753 Method 101 Water Immersion AMSSTD753 Method 100 Copper Sulfate AMSSTD753 Method 102 Passivation AMS2700 *AMSQQP35 *QQP35 ASTM A 967 ASTM A 380 SAE AMSQQP416 Plating, Cadmium (Electrodeposited) This specification covers the requirements for electrodeposited cadmium plating 11 Classification Cadmium plating shall be of the following types and classes, as specified (See 53) Types I As SAE AMSQQP416

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Amazon Com 4 Ms Military Split Lock Washer Cad Ii Per Qq P 416 Type 2 Class 2 Pack Qty 5 000 Ms 40cd By Shorpioen Industrial Scientific

Special Offer AeroPaks offers a customized subscription plan that is costeffective and allows you to choose the number of downloads and Aerospace and Aerospace Material documents you needFind more information hereQQP416F, FEDERAL SPECIFICATION PLATING, CADMIUM (ELECTRODEPOSITED) (01 OCT 1991) S/S BY SAEAMSQQP416, This specification covers the requirements for electrodeposited cadmium platingQQP416F 3292 Phosphate treatment Unless otherwise specified in the contract or order (see 62), the phosphate treatment required for conversion to Type III shall produce a tightly adherent film conforming to Type I of TTC490 33 Detail requirements 331 Thickness of plating Unless otherwise specified (see 62), the

2

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Cadmium plating provides a smooth, adherent surface that is free from blisters, pits, nodules, burning, or other defects when examined visually without magnification It also provides great corrosion resistance Contact ENS Technology for more information regarding FED QQP35C cadmium plating todayQQP416F 1 October 1991 SUPERSEDING Fed Spec QQP416E 18 April 1986 Type II platings should be dry for 24 hours before painting 613 Type III treatment The prime purpose of phosphate finishes (Type III) on electrodeposited cadmium platings is to form a coating base Because of the enhanced adhesion properties, phosphate finishesSAE AMSQQP416, Revision F, March 21 (R) Plating, Cadmium (Electrodeposited) General Usage Processes used for cleaning and cadmium deposition on components heattreated to, or having ultimate tensile strength of 152 ksi (1048 MPa) or higher tensile strength or 34 HRC or higher, should incorporate practices and procedures to minimize hydrogen embrittlement

Ams Qq P 416

Ms Unc Unf Pan Head Las Aerospace Ltd

Cadmium Plating For The Aerospace Industry Har Conn

Cadmium Plating Sheffield Platers

Te Com

Ams Qq P 416 Cadmium Plating Coating Services Incertec

Hex40 Ab 90 11 2 Raychem Screened Backshells Adapters Te Connectivity

Speedcomfly Com

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Ms Nut Datasheet Pdf Nut Equivalent Catalog

Buerklin Com

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

Monadnock Floating Clip Nut Sku Mndnck Clpnut

2

Nas1147 Datasheet Pdf Datasheet4u Com

Nasm Nut Datasheet Pdf Nut Equivalent Catalog

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

2

Sae Ams Qq P 416f 17 Plating Cadmium Electrodeposited

Page 16 Circular Connector Backshells And Accessories

119 23 16

Anello Di Guida Liscio Ajb Tfa Tfc Series Aurora Bearing

Pdf Aerospace Material Specification Passivation Treatments For Corrosion Resistant Steel Jean Franco Gonzalez Academia Edu

Cadmium Plating Color

Ns Yb05c B Instructions Datasheet Pdf Operating Instructions Equivalent Catalog

2

Sae Ams Qq P 416e 16 Sae Ams Qq P 416e 16 Plating Cadmium Electrodeposited

Surface Finishes For Steel Fasteners Wilson Garner Company

Plating Specifications General Information Pdf Free Download

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

2

Catalog Keensertmetric Metalworking Building Materials

Pccfasteners Com

Flathead Threaded Insert Open End Keyless Metric On Pennengineering

2

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

Ansi B18 2 3 Pdf Document

Te Com

Ns Yb05c Controller Datasheet Pdf Display Controller Equivalent Catalog

6 Ms Military Split Lock Washer Cad Ii Per Qq P 416 Type 2 Class Bolt Demon

Te Com

Cadmium Plating Sheffield Platers

Hex40 Ab 90 19 2 Ds Screened Backshells Adapters 90 40 Te Adapter Code Ebay

Rj45 Connectors Rj45 Connectors Interconnect Solutions Worldwide Pdf Free Download

Speedcomfly Com

Oem Spec Description Abex Ps102 Passivate Aero Union Corporation Aups 7 04 Topcoat Aero Union Corporation Aups Topcoat Aerofit Inc Pdf Free Download

Alliedelec Com

Avk Rnss1024 266k Rivetnut Insert 10 24 Unc 3b 216 266 Grip Round Body Countersunk Head Keyed Stainless Steel Passivated Avk R N Rivetnut Threaded Inserts From Bay Supply

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Everyspec Com

2

Ms 663 Ball End Wire Rope Swaging Double Shank

Cadmium Plating Atc 1 Stop Solution Provider For Quality Surface Finishing

Clarke Com Au

Surface Finishing Processes Electroplating

Qq P 416 Tech Information

Pccfasteners Com

Nas333 And Nas334 Ga Screws Aircraft Spruce Canada

Performance Of Three Alternating Coatings

2

Cadmium Plating Macon Georgia

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Ams Qq P 416 E Klzz15gdjqlg

Nasm Datasheet Pdf Datasheet4u Com

Qq P Yasserchemicals Com

Saeams Qq P 416 Datasheet Pdf Itt Industries

Save 50 75 Off Sxch4k81cyml Rivetnut 4 40 050 081 Gr Rnd Body Csk Hd Keyed Locking Steel Cad Ylw Pk Buy Cheap New C3s Oogvoormedia Nl

2

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Flamecorp Com

Sae Ams Qq P 416d 15 Sae Ams Qq P 416d 15 Plating Cadmium Electrodeposited

Sae Ams Qq P 416 R Plating Cadmium Electrodeposited

Integral Keylocking Insert 4140 Alloy Steel Request For Quote Acme Industrial Co

Tye03 Hole Datasheet Pdf Clearance Hole Equivalent Catalog

Thin Dense Chrome Plating Cadmium Plating Ams Qq C 3 Ams Qq P 416

Qq P 416f Abbott Aerospace Canada Ltd

Washers Pdf

2

Approvals California Technical Plating Corp

Mil Spec Washers 10 Ms Military Split Lock Washer Fastenerexpert Us

Qq P 416 Cadmium Plating Keystone Finishing

1155 Ugello Pilota Sm Commerciale Ricambi Grandi Impianti

D7118

Cadmium Plating Corrosion

Ccr274ss A Cres Solid Film Lube Passivate Ccr274cs P E R Per Per Per Ms604r Ams 5731 Astm A 493 Mil L Qq P 35 L F Pdf Free Download

Page 367 Is Rayfast Catalogue Issue 9 17

Cadmium Plating Service Toronto H E Plating Ltd Electroplaters In Toronto Ontario

Cadmium Plating Sheffield Platers

Cadmium Plating Sheffield Platers

Seastrom Mfg Com

Liste Des Approbations Clients Customer Prime Approval Listing Pdf Free Download

An735 40 Loop Type Bonding Metal Clamp E E Trading

2

Everyspec Com

Mil Spec Disc Springs Mil Spec Springs

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Qq P 416 Tech Information

Cadmium Metal Finishing Plastic Ltd

コメント

コメントを投稿